In the global technology landscape, few countries match Singapore’s feats in combining precision manufacturing, smart infrastructure, and polished corporate governance. Its ecosystem—from chip fabs to server assembly lines—paints a vivid picture of industrial efficiency and strategic direction. Today, India aims to replicate that spirit closer to home: creating a Server manufacturing hub and Cable manufacturing plant ecosystem in coastal Andhra Pradesh.

Lessons from Singapore: How it got its tech edge?

Singapore’s journey to becoming a high‑value manufacturing powerhouse wasn’t overnight. Government foresight, consistency, and deep partnerships between agencies and private firms built an ecosystem rooted in:

- Land, logistics, and connectivity: Jurong Island for energy and chemicals; specialist zones for electronics.

- Quality and certification: Standards from ISO to CE to aerospace‑level QA became table stakes.

- Service excellence in tech: Local and international IT firms thrived under pro-business policies.

- Talent and training: Firms like Sp Sysnet worked hand-in-hand with industry.

This potent combination turned Singapore into a global case study in leveraging location, governance, and human capital to boost manufacturing.

Andhra Pradesh: Strategic foundation for a tech manufacturing base

The state of Andhra Pradesh offers many parallels to Singapore’s early strengths:

- An extensive coastline with proposed ports at Visakhapatnam, Krishnapatnam, and Kakinada.

- Coastal industrial corridors and special economic zones tailored to electronics and heavy‑equipment manufacturing.

- State-level programs that offer capital subsidies, power incentives, and customs‑duty exemptions.

- Higher education institutes and emerging technical clusters in cities like Vijayawada, Tirupati, and Visakhapatnam.

With central and state policy support, Andhra has effectively laid the groundwork for becoming India’s Server manufacturing hub and Cable manufacturing plant destination.

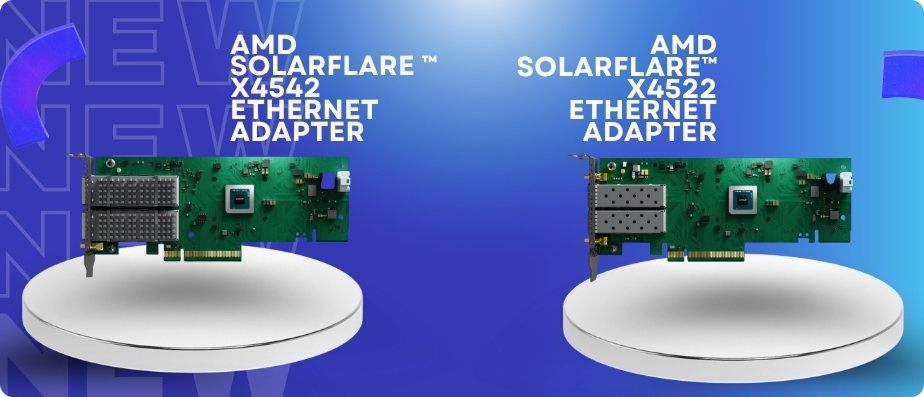

Building a Server Manufacturing Hub

Servers today are more than clustered racks—they’re about supply‑chain excellence, ultra‑clean production, firmware loading, testing, and logistics. Establishing a Server manufacturing hub in Andhra Pradesh means:

- Industrial land parcels with reliable power and micro‑clean rooms.

- Strong logistics for inbound parts (boards, silicon, PSUs) and outbound finished servers.

- Technical workforce development, via workshops and certifications aligned with global OEM and hyperscale standards.

- Collaboration with lead partners and ODMs who can bring expertise to local assembly lines.

Singapore succeeded by wooing Tier‑1 firms and critical suppliers to co‑locate. Andhra needs similar joint‑venture models or anchor investments to build trust, volume, and global visibility.

Setting up a Cable Manufacturing Plant

Power, data, and optical‑fiber cables are essential for connectivity, from hyperscale data centers to smart campuses. A Cable manufacturing plant in Andhra would support the servers, networks, and metro‑economy infrastructure.

Such a plant requires:

- Raw access such as copper, fiber, and polymers.

- Quality labs to test conductivity, shielding, and optical loss.

- Industry standards compliance, like ISO/IEC 11801 or TIA/EIA protocols.

- Export infrastructure, since high‑grade cable can cater not just to Indian markets but to global clients.

Strategically, combining cable manufacturing and server assembly on a logistics-rich industrial corridor helps build a vertically integrated cluster that appeals both to domestic and global OEMs.

IT Services Singapore – Andhra collaboration

Many Singapore‑based IT services expertise firms have built skills in managing manufacturing IT systems: ERP, MES, SCADA, DMF, and more. An IT services Singapore firm, or branch, establishing local presence in Andhra Pradesh would help Indian manufacturing players migrate from manual lines to Industry 4.0 ecosystems.

Key enablers include:

- IT consultants fluent in factory automation and process digitization.

- Cybersecurity expertise to protect server firmware supply chains.

- Data‑center‑grade networking and virtualization support.

- Remote monitoring platforms are tying manufacturing assets to control towers.

By offering their services in Andhra Pradesh, IT services Singapore firms can help factories deploy solutions rapidly—and thereby accelerate quality and scale.

Ecosystem synergies: an Andhra‑Singapore axis

A thriving tech manufacturing cluster needs more than factories—it needs services, standards, finance, and talent ecosystems to thrive:

- Skill upgradation: Joint programs between Singapore institutes (via MOUs) and Andhra technical colleges.

- Quality processes: Adapting Singapore’s lean manufacturing and Six Sigma practices for server and cable factories.

- Policy support: Learning from Singapore’s EDB (Economic Development Board) on incentive design for manufacturing anchors.

- Market linkages: Singapore‑based logistics, trade financing, and export hubs can serve as staging gateways for Andhra‑made tech goods going global.

Why Andhra Pradesh now?

Several factors make this timing ripe:

- India’s push for Atmanirbhar Bharat (self‑reliance) emphasizes electronics manufacturing and local supply chains.

- Global manufacturers are diversifying beyond China, looking for alternative hubs in Asia.

- Andhra’s infrastructure—ports, expressways, and airport expansion is at a pivotal moment of scale-up.

- Quality steel, cable industry inputs, and semiconductor test labs are scaling rapidly in South India.

With these developments, the state can position itself—and India as a whole—as the next generation of tech manufacturing leaders.

Path forward: from pilots to scale

The journey begins with pilot lines: select a global or domestic server OEM to start a small assembly facility. Pair it with a nearby cable plant producing custom runs of quality cables for hyperscalers or defense applications. Engage IT services from Singapore to deploy ERP/MES stacks and shape production discipline.

Once these pilots meet quality and volume targets, scale into broader industrial parks and SEZs. Tie in power‑loop redundancy, fibre‑ring telecom infrastructure, logistics hubs, and cluster‑wide HR training. That synergy becomes compelling not just to Indian demand, but to Latin America, Africa, and Europe—especially under India’s trusted trade networks.

Challenges to address

Building a global‑class hub is ambitious. Key friction points include:

- Attracting anchor investors and global OEMs.

- Overcoming early quality issues and ramping yields quickly.

- Ensuring reliable infrastructure until greenfield facilities stabilize.

- Training skilled workforce en masse and retaining them.

- Securing supply chains for components and raw materials.

These are surmountable—but they require partnerships, policy clarity, and bold investment timelines.

Conclusion

As India charts its next chapter in high‑tech industrialization, Andhra Pradesh is perfectly placed to evolve into a Server manufacturing hub and Cable manufacturing plant powerhouse. By tapping lessons from Singapore—alongside greater involvement from IT services Singapore experts—the state can build a virtuous loop of factory discipline, infrastructure excellence, and export credibility.

With the right anchor investments, policy clarity, and local‑global partnerships in place, this corridor could rival century‑old global clusters. And at the heart of this emerging story lies SP Sysnet, poised to collaborate, deliver, and power India’s future—but that’s a story we’ll save for next time.